While the costing systems are different from each other, management uses the information provided to make similar managerial decisions, such as setting the sales price. For example, in a job order cost system, each job is unique, which allows management to establish individual prices for individual projects. Next is to allocate costs for the completed and incomplete products to the corresponding accounts in order to determine how much money is tied up in the current work-in-progress products. Process costing is probably the most widely used method of cost ascertainment. Process costing refers to a method of accumulating cost of production by process.

Industries

- Let’s assume a unit in ending WIP is about halfway through the process of completion.

- These percentages are used to allocate the total input cost among the joint products.

- Also known as cost-volume-profit analysis, this method is particularly valuable for short-term decision-making and increasing profits.

- As industries evolve and technology advances, the principles of process costing remain relevant, adaptable, and crucial for competitive advantage.

- Organizations engaged in continuous, high-volume production of standardized products should typically implement process costing.

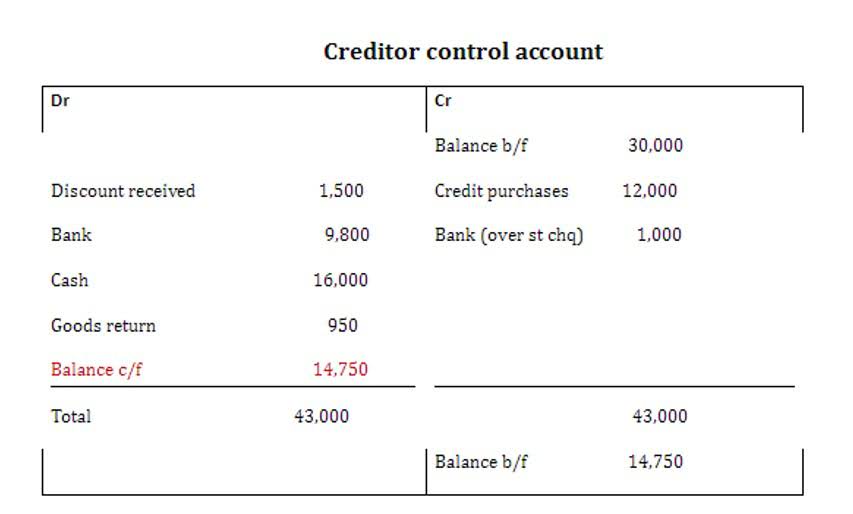

As such, the average cost is not of much use for the purpose of detailed analysis and operating efficiency. (3) The computation Liability Accounts of costs under process costing involves less clerical work and expenses. (4) The production records of each process are kept in such a way as to show the quantity of production and the wastage and scrap and the cost of production of each process for each period. (2) Each Process Account is debited with material cost, labour cost, direct expenses and overheads allocated or apportioned to the process. (14) The production process is pre-determined and a definite sequence of production is followed.

2. Characteristics or Features of Process Costing:

This loss increases the cost of production of the product produced in the process. If the scrap is sold then the sale value of scrap is also shown on the credit of process account which results into decreasing the cost of production. (i) Opportunity or replacement cost method – This method is followed where by-products are utilised by the factory itself as input material for some other process.

Step 3: Track Costs at Each Stage

At its core, this method combines the beginning WIP inventory with the current period’s total production costs and https://www.bookstime.com/ then calculates a single cost per equivalent unit value. This includes the units completed and transferred out of the department or production line. Process costing is a method where costs are assigned to processes or departments rather than individual jobs or orders.

Here the actual cost is divided by the weighted average of products produced. A weighted average of units means the summation of the product of the rate and quantity of each item. The single largest problem with the process costing concept is the use of an estimated percentage of completion of work-in-process at the end of a reporting period. This percentage is a key part of the calculation to assign costs to work-in-process inventory, and so can be used to shift costs into or out of the current period to modify reported levels of profitability.

- This makes it different from job costing, where each job or order is unique and requires individual cost tracking.

- It is widely used in industries where production runs are based on unique client orders, such as custom furniture manufacturing, construction projects, consulting firms, and other custom-based services.

- Applying job order costing and process costing effectively depends on understanding how each method works in business scenarios.

- Upon completion, earn a prestigious certificate to bolster your resume and career prospects.

- Construction companies use job costing to track costs for each building project, accounting for unique materials, labor requirements, and site-specific challenges.

- Dedicated to keeping your business finances operating smoothly so you can focus on your business.

Process costing is a method used by accountants to track costs in continuous manufacturing environments where products are indistinguishable from one another. The first step in process costing is to identify the cost centers, which are typically the various departments or stages in the production process. Each cost center accumulates costs related to materials, labor, and overhead.

Mastering Process Costing: Essential Strategies for Accountants in Continuous Manufacturing

The job costing system is designed to accumulate costs for either individual units or for small production batches. Using either a periodic or perpetual inventory system, we determine the amount of direct materials used during the period. We then process costing calculate the number of units begun and completed during the period, as well as the number of units begun but not completed (work-in-process units).

What is the First Step in Process Costing?

- They are used where the products pass through only some of the processes but not all the processes of the industry.

- This is done by dividing the department’s costs by the units processed.

- Used to apportion costs between work in process and completed output”.

- Chemical companies producing fertilizers, pharmaceuticals, or plastics use process costing because their products flow through standardized mixing, heating, and forming processes.

- In March, the molding department accumulates $50,000 in direct material costs for wax and essential oils and $90,000 in conversion costs, covering wages, facility rent, and overhead.

- The organization can identify such inventory by physically counting the units or through software inbuilt into the manufacturing process.

Choosing between job order costing and process costing can feel overwhelming, but it all begins with understanding your business’s accounting needs. Start by evaluating your production process, workflow, and the nature of your products. Process costing involves the accumulation of costs for lengthy production runs involving products that are indistinguishable from each other.